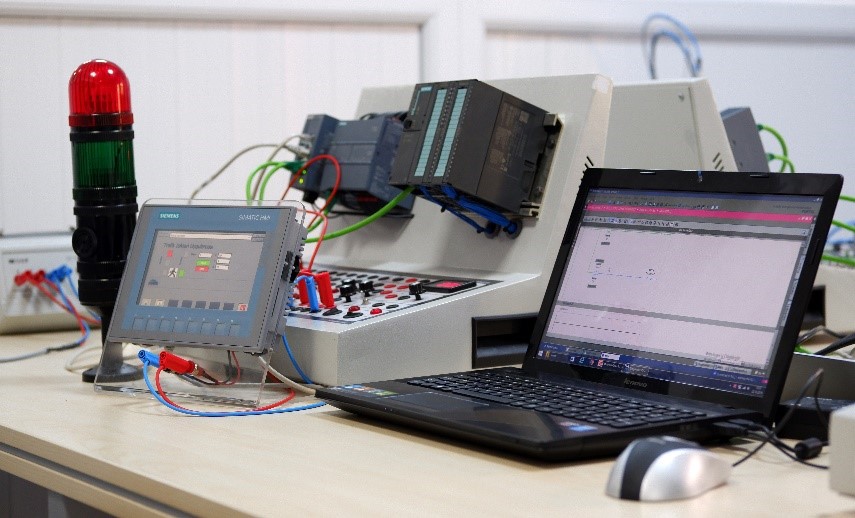

SERVICE PROFESSIONALS FOR INDDUSTRIAL AUTOMATION SYSTEMS OF ALLEN-BRADLEY, SIEMENS, SCHNEIDER, ABB ETC

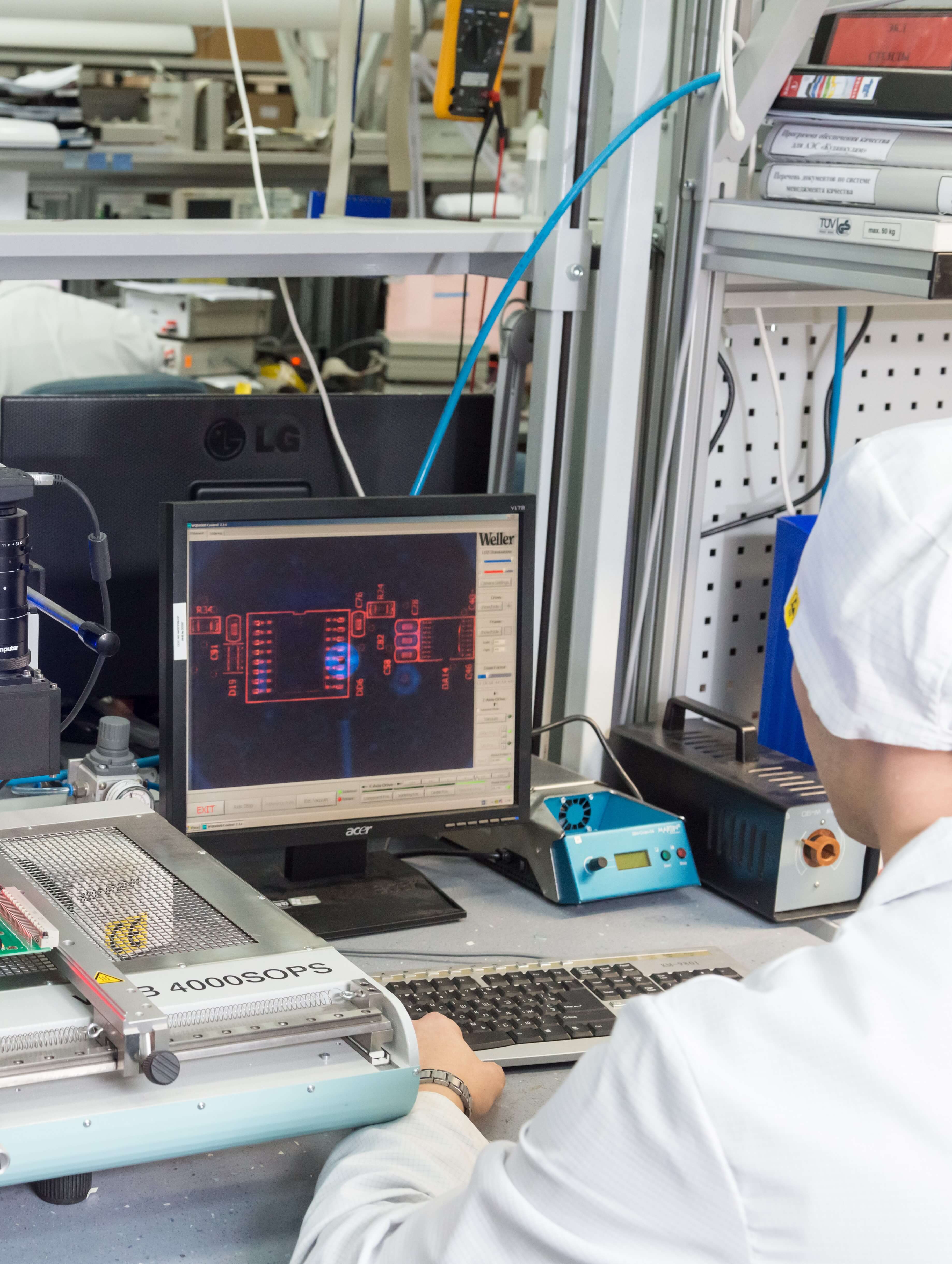

With more than three decades of rich experience in industrial automation and extensive industry process knowledge, we are the leading platform of competent service & solution providers for execution of legacy as well as latest control systems across multiple processes & discrete industries. The services from us & our partners cover the complete project lifecycle from concept design, development, testing, startup & commissioning to site support and also repair services as well.

Driven by our ‘Global Delivery Model’ and latest project management practices that facilitate planning and monitoring of the projects, we share a proven track record of consistently delivering world class quality automation engineering services.